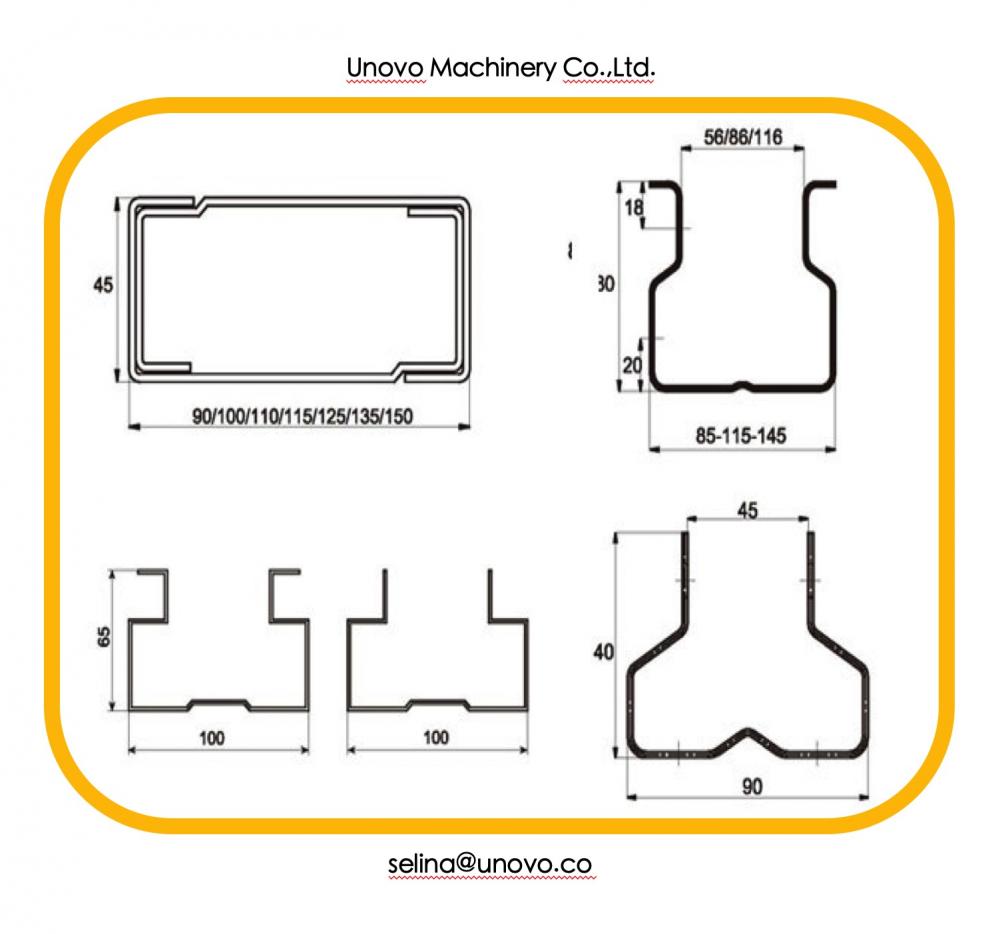

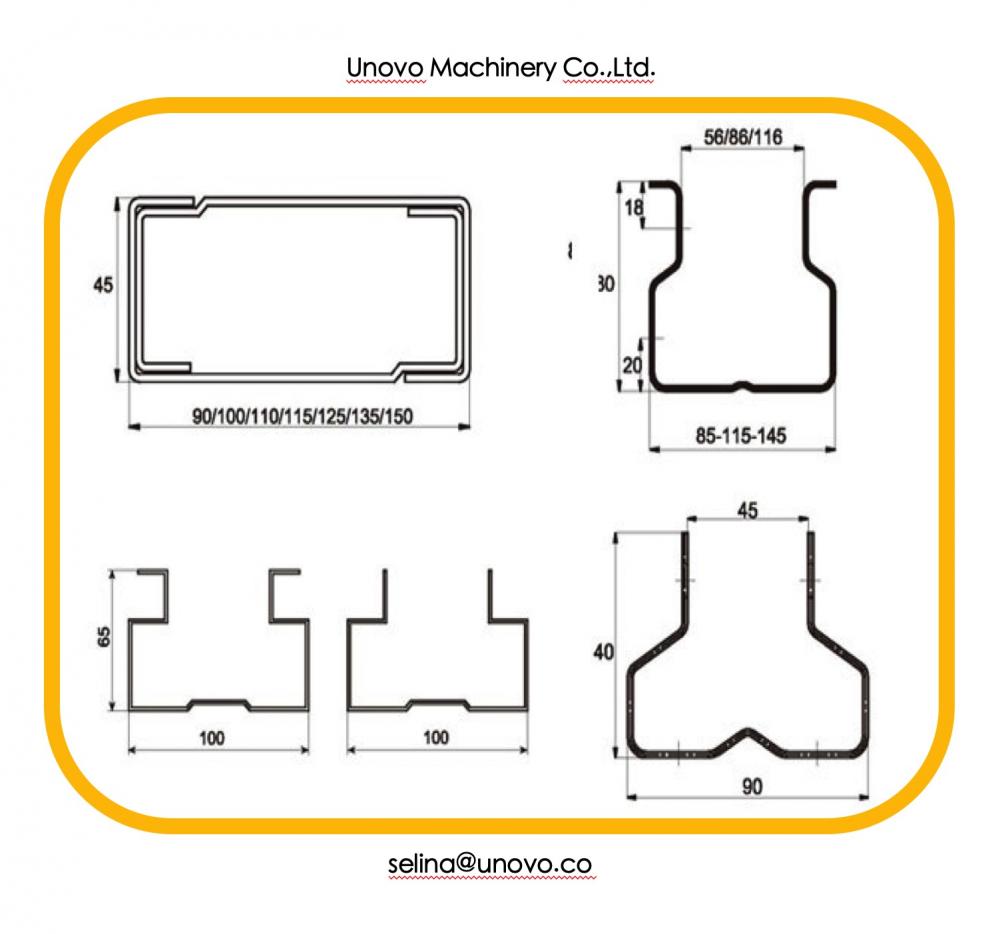

Unovo Machinery provides various Steel Warehouse Customizable Heavy Duty Racks Storage Shelf, High quality Heavy Duty Shelf / Storage Rack / Cold Storage Shelf / Industrial Racking, we developed storage rack roll former production machine

Machine Description »»» UNOVO Machine Information:

storage rack roll former production machine, This machine use to produce metal storage rackl, from a coil to finished strut channel product only finished by one production line, the machine line has 3in1 equipment which has de-coiler for coil hold, leveling machine for making coil sheet flat, and then use servo feeder to feed sheet length to punching machine as PLC program setting, hydraulic or mechanical punching machine has several individual cyliner which could be seperately controlled by PLC, so it's easy to achieve punching any hole or slot or notching at any length side of sheet. After finish holes punching on sheet, then Roll forming machine will forming the profile as the drawing requirement step by step. After profile forming there has straightening device for adjusting the straightness of finished product. And then using hydraulic cutting device to cut your length,finally stand tables ready for packing. It is full automatic machine line and quite easy to use it, only require 3 people for operation.

»»» Product Information:

|

1.

|

3in1 Machine [De-coiler+Leveling+Servo Feeder]

|

1 set

|

|

2.

|

Hydraulic Punching Machine

|

1 set

|

|

3.

|

Roll Forming Machine

|

1 set

|

|

4.

|

Straightness Device

|

1 set

|

|

5.

|

Servo Hydraulic Cutting Machine

|

1 set

|

|

6.

|

Hydraulic Station

|

2 sets

|

|

7.

|

Computer Control Box

|

2 sets

|

|

8.

|

Product Stand Tables

|

2 sets

|

|

9.

|

Punching Molds

|

5 units

|

|

10.

|

Tool Box

|

1 box

|

|

Roller Former Machine

|

Motor Brand:

|

SIEMENS

|

|

Motor Power:

|

15*2KW

|

|

Motor Quantity:

|

2 Sets

|

|

Roller Material

|

GCr15 bearing steel

|

|

Forming Stands:

|

18 stations

|

|

Forming Structure:

|

Guiding Column

|

|

Forming Speed:

|

0~15M/min

|

|

Shaft Diameter:

|

75mm ,optional

|

|

Shaft Material:

|

40Cr

|

|

Transmission Type:

|

Worm gear box

|

|

Bearing Brand:

|

HRB [China Best]

|

|

Bearing Type:

|

Taper Bearing Needle Roll Bearing

|

|

Bolt Grade:

|

8.8 Grade

|

|

Voltage:

|

380V, 50Hz, 3Phase

|

|

Safety Cover:

|

Optional

|

.png) Contact Now

Contact Now